Reduce Frame Repair Costs: DIY Tips vs Professional Solutions

Understanding that frame repair costs are higher than dent repairs due to complexity and labor, with…….

In today’s world, where structural integrity is paramount across various sectors, understanding the intricacies of frame repair costs has become essential. This comprehensive article aims to dissect and demystify the multifaceted aspects of frame repair costs, offering valuable insights for businesses, policymakers, and enthusiasts alike. By exploring its historical evolution, global impact, economic implications, technological innovations, regulatory frameworks, and real-world applications, we will provide a holistic view of this critical concept.

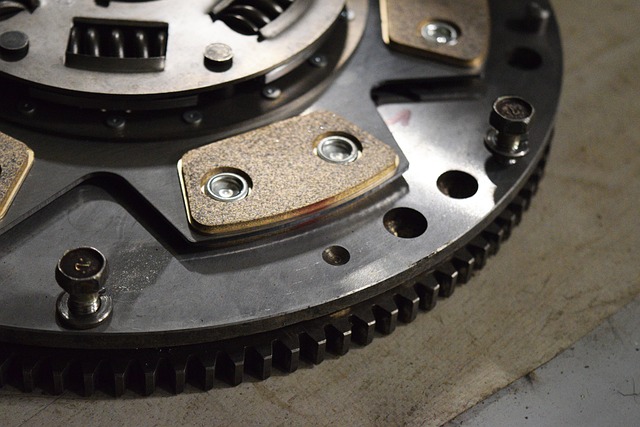

Frame repair cost refers to the financial expenditure involved in restoring or reinforcing structural frames, primarily in construction, automotive, and transportation industries. It encompasses a wide range of activities, from assessing damage to replacing components, ensuring structures’ safety and longevity. This cost is a vital consideration in project budgeting, risk management, and overall quality control.

The core components of frame repair cost include:

Inspection and Assessment: Initial stage involves detailed examination of the frame to identify defects, damages, or structural weaknesses using advanced diagnostics and non-destructive testing methods.

Materials and Parts: This includes purchasing new or replacement parts such as beams, columns, joints, and connectors, considering factors like material type, grade, and quantity.

Labor Costs: The expense incurred by skilled labor for disassembly, repair, reinforcement, and reassembly of the structural frame. Labor rates vary based on geographic location, complexity of work, and availability of specialists.

Overhead and Profit: General overhead costs associated with project management, insurance, equipment maintenance, and contractors’ profit margins.

Historically, frame repair has been a manual, labor-intensive process, but technological advancements have introduced more efficient and precise methods, impacting cost dynamics.

The influence of frame repair cost extends globally, with varying trends across regions:

North America and Europe: These regions have well-established construction industries, where strict building codes drive higher standards for structural integrity. Consequently, frame repair costs are relatively higher due to the use of advanced materials and specialized labor.

Asia Pacific: Rapid urbanization in countries like China and India has led to a surge in construction activity, resulting in increased demand for frame repairs, particularly in infrastructure projects. Local markets witness competitive pricing due to a vast pool of skilled laborers.

Middle East and Africa: These regions often face unique challenges, such as extreme climates affecting building structures. This necessitates specialized repair techniques and materials, impacting cost structures.

Global trends show a growing emphasis on sustainable construction practices, which can influence frame repair methods and costs. Recycled materials and innovative design strategies aim to reduce long-term maintenance expenses.

The economic aspects of frame repair cost are multifaceted:

| Market Drivers | Impact |

|---|---|

| Construction Industry Growth | Rising construction activities drive demand for frame repairs, creating a robust market. |

| Infrastructure Development | Governments’ focus on infrastructure projects in developing nations increases the need for structural enhancements and repairs. |

| Regulatory Compliance | Stringent building codes encourage investments in high-quality frame repairs, ensuring safety and longevity of structures. |

Investment Patterns:

Public Sector: Governments often fund large-scale infrastructure repair projects, driving substantial investments in frame repairs for public buildings and transportation networks.

Private Sector: Construction companies incorporate frame repair costs into project budgets to ensure structural integrity and minimize future maintenance costs.

Insurance Industry: Insurance providers factor in frame repair costs when assessing risks and setting premiums for properties prone to structural damage.

Technological innovations have significantly impacted frame repair cost and efficiency:

Computer-Aided Design (CAD) Software: Engineers and architects utilize CAD programs to create detailed digital models of frames, enabling precise measurements and design modifications, reducing manual errors and associated costs.

3D Printing: This technology allows for the rapid creation of customized structural components, minimizing waste and offering cost-effective solutions for complex repairs.

Advanced Materials: The development of high-performance, lightweight materials reduces weight, enhances structural integrity, and lowers long-term maintenance expenses. Fiberglass composites, carbon fiber reinforcement, and advanced alloys are examples of such materials.

Robotic Systems: Automated robots assist in welding, bolting, and painting, increasing productivity while ensuring consistent quality. These systems can work in hazardous environments, reducing labor exposure to risks.

Regulatory frameworks play a crucial role in shaping frame repair cost across different jurisdictions:

Building Codes and Standards: Local and national governments enforce building codes that dictate minimum structural requirements, impacting the type and cost of repairs needed. Adherence to these standards ensures safety and guides investment decisions.

Environmental Regulations: Strict environmental policies may influence frame repair methods, particularly in regions with severe weather conditions. For example, regulations promoting energy efficiency can drive the use of lightweight, sustainable materials.

Insurance Industry Oversight: Insurance companies, through their risk assessment practices, indirectly shape frame repair costs by influencing reconstruction and renovation budgets for insured properties.

Despite advancements, frame repair cost faces several challenges:

Labor Shortages: Skilled labor shortages in certain regions can drive up wages, affecting project budgets, especially for specialized repairs.

Material Costs Fluctuations: Volatile global markets impact material costs, making it challenging for contractors to predict and manage expenses accurately.

Lack of Standardization: Inconsistent industry standards and practices across regions create complexities in cost estimation and comparison, hindering efficient project planning.

To address these issues:

Skills Development Programs: Governments and industry bodies can collaborate on training initiatives to bridge labor shortages and ensure a skilled workforce.

Material Sourcing Strategies: Diversifying material suppliers and adopting long-term procurement plans can help stabilize costs.

Standardization of Practices: Developing universal guidelines for frame repair methods and cost estimation will enhance transparency and comparability.

Challenge: Restoring a medieval city center in Florence, Italy, required intricate frame repairs to preserve historic buildings while meeting modern safety standards.

Solution: Local artisans collaborated with engineers to develop custom repair solutions using traditional techniques and advanced materials. The project emphasized preserving authenticity while ensuring structural integrity.

Outcome: Successful restoration received international acclaim, attracting tourists and boosting local pride. The cost-effective approach involved public-private partnerships and government incentives for historic preservation.

Challenge: Building a skyscraper in dense Tokyo required innovative frame repair solutions to navigate tight spaces and severe weather conditions.

Solution: Engineers utilized advanced robotic welding systems and prefab components, minimizing on-site assembly and ensuring rapid repairs during construction.

Outcome: The project delivered an efficient, cost-saving design, achieving higher productivity without compromising safety. This case highlights the impact of technology on frame repair cost reduction.

The future of frame repair cost looks promising with several emerging trends:

Digital Twin Technology: Creating digital replicas of physical structures enables real-time monitoring, predictive maintenance, and efficient planning for repairs, reducing costs over time.

Sustainable Construction: The focus on green buildings and circular economy practices will drive demand for eco-friendly frame repair methods, potentially lowering long-term maintenance expenses.

Offsite Construction: Pre-fabrication and modular construction techniques gain traction, offering cost savings and faster repairs for complex frames.

In conclusion, frame repair cost is a dynamic field, influenced by global trends, technological advancements, and regulatory frameworks. Understanding its core components, historical context, and economic implications is essential for stakeholders across industries. The case studies presented illustrate successful applications, highlighting the importance of innovation, collaboration, and adherence to standards.

As the construction and transportation sectors continue to evolve, frame repair cost will remain a critical aspect of project planning and budgeting. Embracing emerging trends and learning from challenges will ensure sustainable growth, enhancing structural integrity while optimizing costs.

Q: How do I estimate the cost of frame repairs for my property?

A: Estimate costs by gathering detailed information about the type and extent of damage. Consider local market rates for labor and materials, consult with professionals, and factor in regulatory requirements.

Q: Can technology really reduce frame repair costs significantly?

A: Absolutely! Technological advancements like 3D printing, robotic systems, and digital design tools offer cost-saving solutions. They enhance efficiency, minimize waste, and reduce the need for extensive manual labor.

Q: What are some sustainable options for frame repairs?

A: Opt for eco-friendly materials like recycled steel, bamboo, or composite materials. Consider energy-efficient methods, such as passive solar design, to reduce long-term maintenance costs and environmental impact.

Q: How do building codes impact frame repair cost?

A: Building codes dictate structural requirements, influencing the complexity of repairs. Compliance with these standards ensures safety but may add to the cost due to stringent requirements for materials and construction methods.

Understanding that frame repair costs are higher than dent repairs due to complexity and labor, with…….

Welding is a critical, precise process in vehicle collision repair, especially for frame restoration…….

Frame repair costs vary greatly across regions, influenced by labor expenses, local competition, and…….

Frame repair costs vary based on labor rates influenced by repair complexity, shop reputation, locat…….

Calculating frame repair costs involves understanding various components like damage extent, special…….

Frame damage significantly impacts frame repair cost, ranging from simple adjustments to extensive r…….

Understanding frame damage and repair techniques is key to determining frame repair cost. Simple rep…….

Regular inspections and proactive handling of vehicle issues are key to managing frame repair cost……..

Understanding frame damage is crucial for estimating frame repair cost, which varies based on severi…….

When evaluating high frame repair cost estimates, understand that meticulous work is required to saf…….